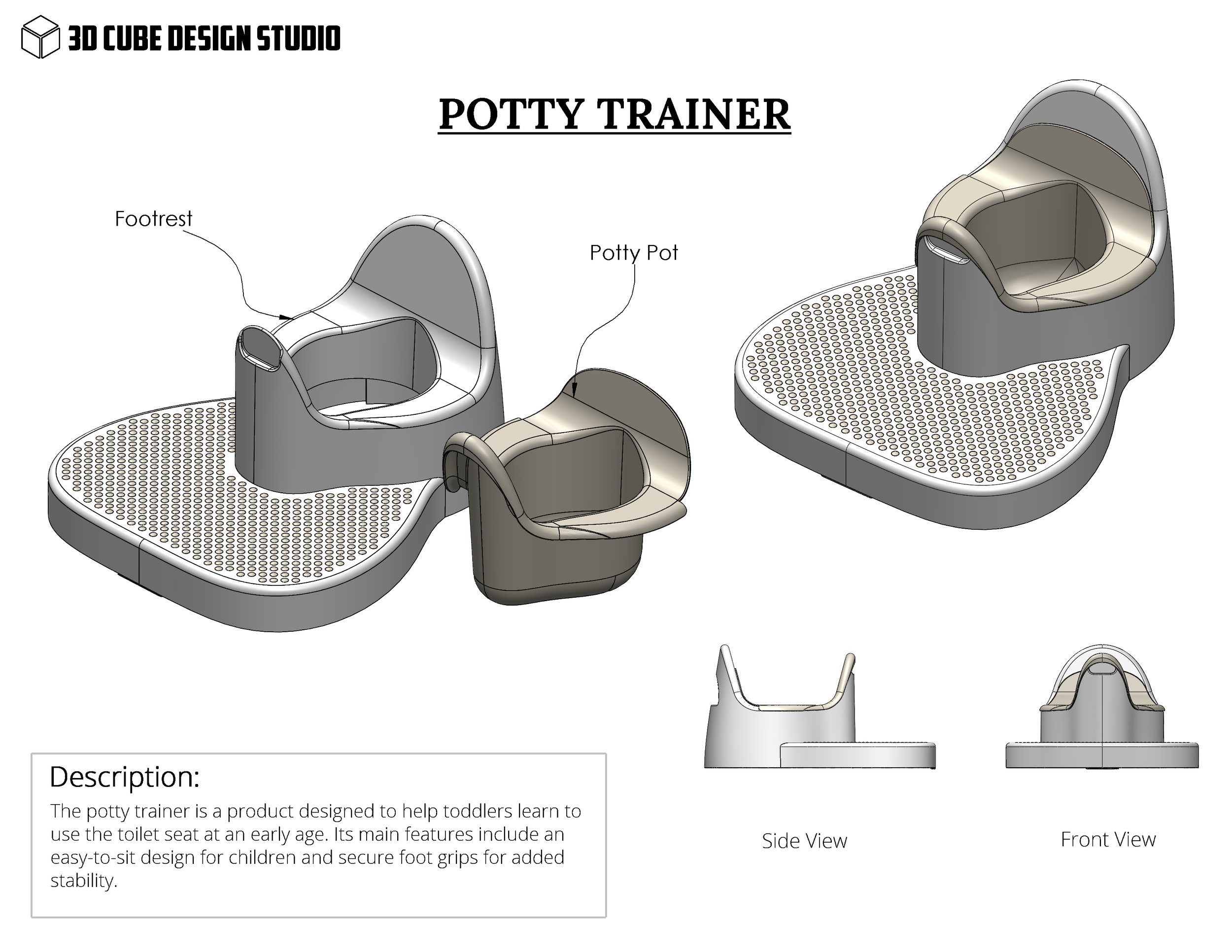

Potty Trainer for toddlers

A drawing view of potty trainer

Objective

The Potty Trainer was designed to help toddlers transition from diapers to using a toilet seat, fostering independence at an early age. The product needed to prioritize safety, comfort, and ease of use while being attractive to children and convenient for parents. The design’s primary goals included:

Ergonomic Comfort: A seat designed to suit toddlers’ anatomy and provide a stable sitting posture.

Safety Features: Non-slip surfaces and sturdy construction to ensure stability during use.

Ease of Cleaning: A removable potty pot for quick and hassle-free cleaning.

1. Concept Development

The design process began by studying existing potty trainers and interviewing parents to identify common pain points. The insights revealed:

Top Priorities: Stability and non-slip features to avoid tipping accidents.

Comfort Issues: Many potty trainers lacked ergonomic back and arm support for toddlers.

Cleaning Challenges: Parents emphasized the need for a removable inner potty pot for easy maintenance.

With these insights, the design direction focused on combining safety, functionality, and an appealing aesthetic to encourage use by toddlers.

2. Sketching & Initial Concepts

Initial sketches explored various configurations for the potty trainer, focusing on:

A Wide Base: To prevent tipping and ensure stability.

Back and Arm Support: Curved support elements to ensure a comfortable and secure seating position for toddlers.

Footrest Integration: A large footrest with anti-slip grips to help toddlers stabilize themselves while seated.

Removable Potty Pot: A pull-out pot design to simplify the cleaning process for parents.

Three key concepts were presented to the client, who selected a design with a curved backrest, a contoured seat, and an integrated footrest for added stability and comfort.

3. 3D CAD Modeling

Using SolidWorks, the chosen concept was modeled in 3D to refine the design and incorporate functional details:

a. Ergonomics

The seat was contoured to fit a toddler’s anatomy, providing a comfortable and secure sitting experience. The backrest was curved for lumbar support, while side grips ensured additional stability.

b. Base and Footrest

The base was widened and slightly elevated, with an integrated footrest featuring a textured non-slip surface to prevent accidental slips. The footrest was large enough to accommodate various toddler sizes.

c. Potty Pot Design

A removable potty pot was designed with a smooth edge for easy removal and cleaning. The pot was recessed into the main body to ensure it stayed in place during use but was still easily accessible for parents.

d. Material Selection

Polypropylene (PP): Chosen for its lightweight, non-toxic, and easy-to-clean properties.

Silicone Grips: Used for the anti-slip footrest and rubber pads under the base for enhanced stability.

4. Prototyping

Prototypes were created using 3D printing for the main body and inserts, while silicone was used for the foot grips. Testing focused on:

Stability Testing: Ensuring the wide base and anti-slip grips prevented tipping during use.

Ergonomics Testing: Toddlers tested the seat’s comfort and fit. Parents provided feedback on whether the potty trainer encouraged proper sitting posture.

Ease of Cleaning: Parents evaluated the removable potty pot, confirming it could be emptied and cleaned effortlessly.

Field testing revealed positive feedback on the overall stability and comfort. However, the footrest height required adjustment to better suit smaller toddlers.

5. Testing & Refinement

Based on testing feedback, the following refinements were made:

Height Adjustment: The seat height was slightly reduced to accommodate smaller toddlers while maintaining ergonomic posture.

Potty Pot Enhancements: Handles were added to the removable potty pot for easier grip and removal.

Anti-Slip Features: The silicone grips were expanded to cover a larger area of the footrest for enhanced traction.

Material Optimization: The overall structure was reinforced with ribbing on the underside to improve durability while keeping the product lightweight.

6. Final Design and Manufacturing Handoff

With the refinements complete, the final design was prepared for mass production. Deliverables included:

Detailed Technical Drawings: 2D drawings with dimensions, tolerances, and assembly instructions.

3D CAD Files: STEP and STL files for manufacturing, including mold-ready designs.

Material Specifications: Recommendations for child-safe materials, such as BPA-free polypropylene and food-grade silicone for grips.

Assembly Guide: Clear instructions for assembling the base, potty pot, and backrest during manufacturing.

The product was optimized for injection molding, with minimal parts to simplify assembly and reduce production costs.