Adjustable Phone Holder

A drawing view of phone holder

Objective

The adjustable Phone Holder was designed to meet the growing demand for hands-free solutions for drivers. The product aimed to provide a secure, universal grip for smartphones, ensuring accessibility and visibility while driving. The key challenges were to create a compact, durable design that could attach easily to car dashboards or windshields and remain stable during motion.

1. Concept Development

The project began with an analysis of existing phone holders, identifying the following customer pain points:

Unstable Grips: Many holders failed to keep phones secure on bumpy roads.

Limited Compatibility: Some designs couldn’t accommodate larger phones or cases.

Weak Suction Cups: Holders often detached from dashboards or windshields over time.

Restricted Adjustability: Limited pivoting made it difficult to achieve an optimal viewing angle.

Our primary goals were:

Universal Fit: A spring-loaded mechanism to hold various phone sizes securely.

Strong Attachment: A robust suction system with locking mechanisms for added stability.

Full Adjustability: A ball-joint system allowing 360-degree rotation for flexible viewing angles.

2. Sketching & Initial Concepts

Multiple sketches explored different attachment mechanisms, grip designs, and adjustability options. Early sketches focused on:

A suction-based mount with a locking clip for secure attachment.

A spring-loaded gripper to adjust to a wide range of phone sizes.

A ball-and-socket mechanism to enable smooth rotation and tilt.

Three concept variations were presented, and the client selected a design that combined a suction-cup base with a spring-loaded gripper and adjustable ball-joint for maximum functionality.

3. 3D CAD Modeling

Using SolidWorks, the chosen concept was translated into a detailed 3D model. The design focused on optimizing functionality and manufacturability:

a. Main Body and Gripper

The gripper arms were designed with rubberized pads to provide a non-slip surface for securely holding smartphones without scratching them.

The spring mechanism allowed for a universal fit, accommodating phone widths from 2.5 to 4.5 inches, including phones with cases.

b. Suction Cup System

A durable suction cup with a lever-lock mechanism was designed to create a vacuum seal, ensuring the holder stayed firmly attached to dashboards or windshields.

Textured silicone material was used for the suction cup to improve grip on uneven surfaces.

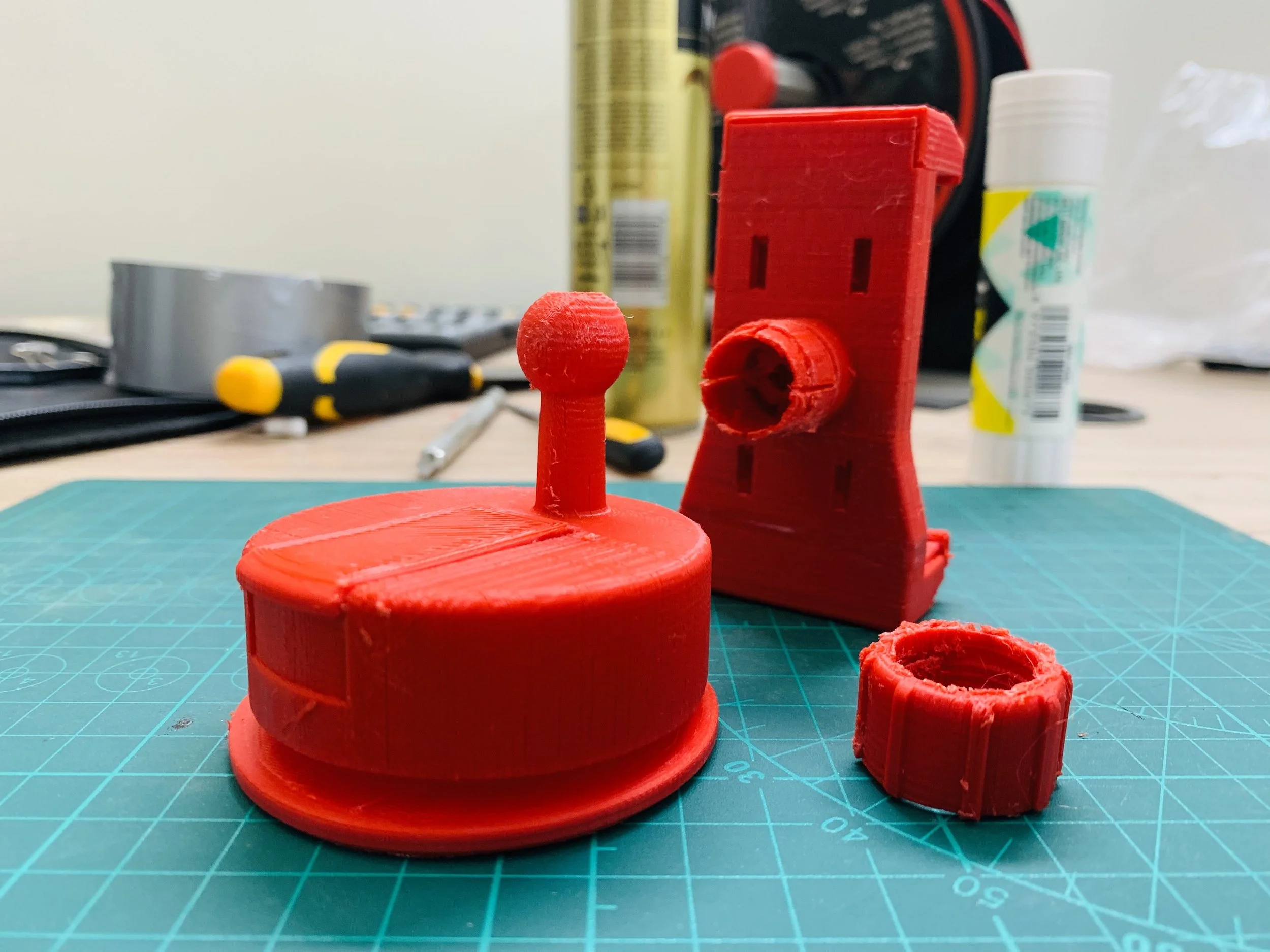

c. Ball-and-Socket Joint

The ball-joint mechanism allowed for 360-degree rotation and 180-degree tilt, enabling users to position their phones at the perfect viewing angle.

A support nut was added to tighten the joint and lock the phone in place once adjusted.

d. Material Selection

ABS Plastic: Chosen for the main body due to its lightweight, durability, and cost-effectiveness.

Silicone Rubber: Used for the suction cup and gripper pads to ensure slip resistance and longevity.

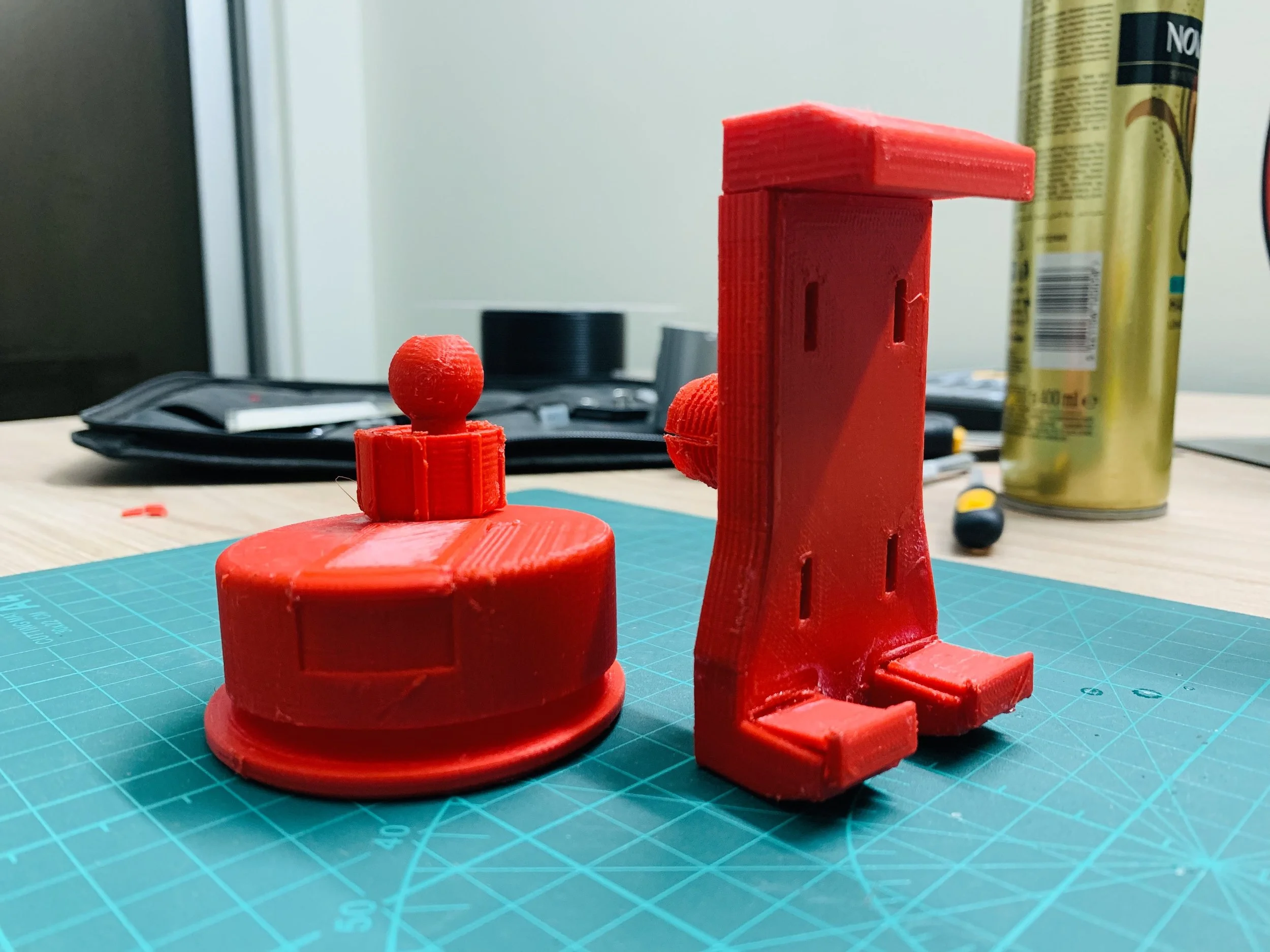

4. Prototyping

Prototypes were 3D printed using PLA material for the structural components, while silicone was used for the gripper pads and suction cup. Testing focused on:

Grip Strength: Evaluating the spring-loaded mechanism’s ability to securely hold various phone sizes, including larger models like the iPhone Pro Max.

Suction Cup Performance: Testing the holder on different surfaces (smooth glass, textured dashboards) and under varying conditions (temperature changes, vibration).

Adjustability: Ensuring the ball-joint provided smooth and precise rotation without loosening during use.

Durability: Simulating repeated attachment and detachment to test component longevity.

Testing revealed that while the overall design performed well, the suction cup needed a stronger locking mechanism to prevent detachment during long drives.

5. Testing & Refinement

Based on feedback, refinements were made to improve the design:

Enhanced Suction Lock: The lever-lock system was strengthened with a tighter hinge mechanism to ensure consistent suction, even on textured surfaces.

Reinforced Spring Mechanism: A sturdier spring was added to increase the gripper’s clamping force for larger, heavier phones.

Rubber Pads Expansion: The surface area of the gripper pads was increased to provide better contact with the phone, further reducing the risk of slippage.

Heat Resistance: Materials were upgraded to handle high temperatures inside parked cars without deforming or losing suction strength.

6. Final Design and Manufacturing Handoff

The final design was finalized after extensive testing and validation. Deliverables prepared for mass production included:

3D CAD Files: STEP and STL files optimized for injection molding.

2D Technical Drawings: Complete drawings with dimensions, tolerances, and assembly instructions.

Material Recommendations: ABS plastic for the main body, silicone for the suction cup and gripper pads, and a stainless steel spring for durability.

Assembly Guide: Detailed steps for assembling the holder, including securing the suction mechanism and integrating the gripper with the main body.

Manufacturing was optimized for injection molding and silicone over-molding, minimizing production costs while ensuring consistent quality.