Nose Filter for Asthma Patients

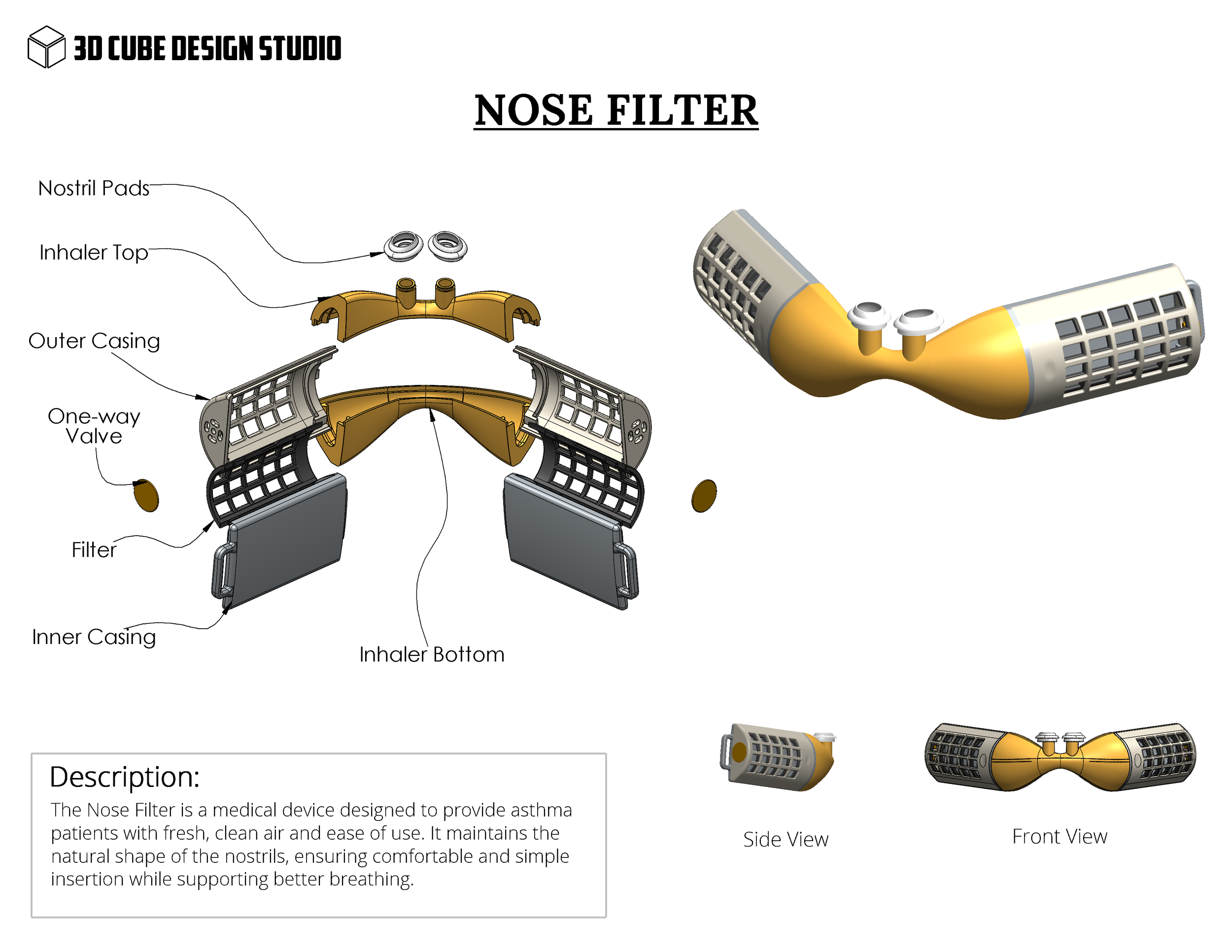

A drawing view of nose filter

Objective

The goal was to design an innovative Nose Filter aimed at providing asthma patients with fresh, clean air while ensuring comfort, ease of use, and improved breathing support. The device needed to filter harmful particulates and allergens while maintaining a discreet, ergonomic design that seamlessly fits into the user’s nostrils.

1. Concept Development

The project began by addressing key challenges faced by asthma patients:

Exposure to allergens, pollutants, and irritants.

The need for a discreet and lightweight device that would not obstruct natural breathing.

Durability and reusability, coupled with easy cleaning and maintenance.

Our initial research involved reviewing existing nasal filters and patient feedback to identify limitations, such as discomfort during prolonged use and inefficiency in air filtration. From this, the key design goals emerged:

Ergonomic Fit: Design to conform to the natural nostril shape for comfort and ease of insertion.

Effective Filtration: Incorporate replaceable filters capable of capturing particulates and allergens.

Lightweight Design: Use minimal materials for a compact and discreet product.

Enhanced Airflow: Include one-way valves to support unidirectional airflow, preventing air blockage.

2. Sketching & Initial Approval

Hand-drawn sketches were created to explore design ideas. These included various shapes for the nasal casing and configurations for the filter placement. Key considerations during sketching were:

The contour of the outer casing, ensuring a snug fit without irritation.

Placement of filters and one-way valves to maximize airflow efficiency.

A split casing structure for easy assembly and filter replacement.

Three design concepts were presented, and the client selected a configuration featuring a dual-nostril casing connected by a central airflow bridge. This design ensured a balance between functionality and comfort.

3. 3D CAD Modeling

Using SolidWorks, the selected concept was transformed into a detailed 3D model. The design process focused on:

a. Outer Casing

The outer casing was designed with a grid structure to house the filters while maintaining a low-profile aesthetic. This grid reduced weight and allowed airflow while securely holding the filters in place.

b. Filter System

Filters were designed to be replaceable, with slots in the inner casing to hold them securely. The material specified was a high-efficiency particulate air (HEPA)-grade filter for maximum pollutant capture.

c. One-Way Valves

The design included two one-way valves, placed at the top of each nostril casing. These valves allowed inhalation through the filter but directed exhalation outward, preventing air stagnation inside the device.

d. Ergonomics

The inhaler’s shape followed the natural contours of the nasal cavity to ensure a comfortable fit, with nostril pads added to provide cushioning. The central bridge was contoured to maintain proper positioning and balance during use.

4. Prototyping

Prototypes were created using 3D printing with resin materials to replicate the final product's size and structure. Prototyping allowed for iterative testing of:

Fit and Comfort: The initial prototype was tested with a small group of users to assess the ergonomic design. Adjustments were made to reduce pressure on the nostrils.

Airflow Efficiency: The one-way valve functionality was tested to ensure smooth and unidirectional airflow during inhalation and exhalation.

Filter Replacement: The filter slots were checked for ease of removal and reinsertion without compromising stability.

Field testing highlighted the need for a softer material for the nostril pads to improve user comfort during extended use. The central bridge was also refined to prevent shifting during physical activities.

5. Testing & Refinement

Based on feedback from prototype testing, the following refinements were made:

Nostril Pads: Upgraded to a medical-grade silicone material for added comfort and durability.

Outer Casing: The grid pattern was optimized to balance strength and airflow, with slightly enlarged openings to reduce resistance.

One-Way Valves: The valve mechanism was redesigned with a thinner, more flexible diaphragm to improve responsiveness during breathing cycles.

Inner Casing: The filter slots were redesigned for a tighter fit, ensuring the filters stayed in place even during physical movement.

FEA (Finite Element Analysis) simulations validated the device’s structural integrity under different stress conditions. Airflow simulations confirmed that the device maintained adequate oxygen delivery rates while filtering out particulates effectively.

6. Final Design and Manufacturing Handoff

The final design consisted of an injection-molded outer and inner casing with replaceable filters and soft silicone nostril pads. All manufacturing files, including:

2D Technical Drawings with precise dimensions, tolerances, and assembly details.

Material Specifications: Polycarbonate for the casing (lightweight and durable), medical-grade silicone for the nostril pads, and HEPA-grade filter material.

Assembly Guide: Detailed instructions for manufacturing assembly and user filter replacement.