Beer Can Holder for Ski/Snowboard Helmets

3D Rendering of Ski helmet with beer can holder mounted on one side

Objective

The project aimed to create a functional, lightweight, and visually appealing beer can holder specifically designed to attach securely to ski or snowboard helmets. This innovative accessory would allow users to carry beverage cans hands-free while on the slopes, offering a blend of practicality and novelty.

1. Concept Development

The idea began with a client request for a product that could attach two beverage cans to a helmet, primarily targeting skiers and snowboarders who wanted a fun way to carry drinks while on the move. Key design requirements included:

Secure attachment to the helmet to prevent spillage or detachment during activity

Compatibility with different helmet types and can sizes

Lightweight and durable materials that would withstand low temperatures and rough handling

Aesthetically appealing with a modern, sporty look

We gathered product inspiration, analyzed competitive novelty products in outdoor sports accessories, and identified the structural challenges associated with helmet attachments.

2. Sketching & Approval

To kick off the design process, initial sketches were created to explore potential shapes and attachment mechanisms. We presented these sketches to the client, focusing on three main aspects:

Attachment Mechanism: A rail clip system that would allow the holder to secure onto the elastic band of ski goggles was proposed. This would keep the product adaptable to most helmet setups.

Weight Distribution: To prevent the helmet from tipping to one side, a two-can design was considered, allowing one holder on each side.

Aesthetic Appeal: We suggested an open-frame design with sleek cutouts to reduce weight and enhance the holder’s visual appeal.

After feedback and minor adjustments, the design was approved, moving us into the 3D modeling phase.

3. 3D CAD Modeling

In this phase, we translated the sketches into precise 3D models using SolidWorks. Each component was meticulously modeled to ensure functionality and durability, focusing on:

Can Holders: Two holders were designed to fit 8.4 oz and 12 oz cans, allowing versatility. The open-frame design reduced material use, minimizing weight without compromising stability.

Rail Clip: A rail clip was added to each holder, enabling it to latch securely onto the elastic band of ski goggles.

Velcro Strap Integration: To balance the weight distribution, we designed slots on each holder for a connecting velcro strap. This strap would extend across the helmet, from ear to ear, stabilizing the load.

The CAD models allowed for virtual testing and client feedback on structural integrity, visual appearance, and compatibility with helmet dimensions. Iterations were made, mainly focused on refining the rail clip’s shape and ensuring a snug can fit.

4. Prototyping

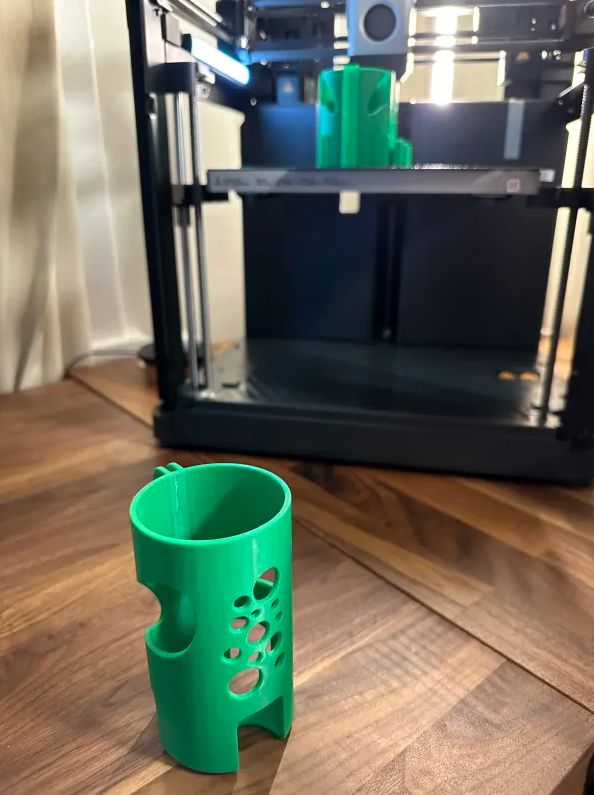

After finalizing the CAD design, we proceeded with 3D printing prototypes. Using PLA plastic for initial testing allowed us to evaluate the fit, weight, and attachment effectiveness. Multiple prototypes were created:

Green Prototype: This model allowed us to test the fit on different helmet types, confirming the compatibility of the rail clip with various goggle bands. The prototype was also tested for stability when worn, ensuring it would stay securely in place.

Black Prototype: A refined prototype with minor adjustments in the clip thickness and holder openings. This prototype was tested with both 8.4 oz and 12 oz cans to confirm a snug fit and easy removal while retaining the can securely.

Field testing showed promising results, though adjustments were required to strengthen the rail clip attachment further. Additionally, feedback revealed that the rectangular slot added at the top of each holder provided essential support for the cans, preventing any lateral movement.

5. Testing & Refinement

With prototypes in hand, we moved to more rigorous testing. Users wore the helmet with holders attached and tested its stability while engaging in simulated skiing movements. Based on feedback, several refinements were implemented:

Clip Reinforcement: The rail clip material was thickened slightly to withstand higher tension and prevent detachment.

Weight Distribution: We finalized the placement of the velcro strap to ensure optimal balance across the helmet.

Material Selection: For production, a more durable plastic like ABS or nylon was suggested to improve durability and weather resistance in colder environments.

Testing confirmed that the final design was secure, lightweight, and comfortable, with no discomfort to the wearer due to the additional weight.

6. Final Design and Manufacturing Handoff

Upon approval of the refined prototypes, we prepared the final technical drawings and 3D models with manufacturing specifications, including:

Material Recommendations: ABS or nylon for the final product due to their impact resistance and low-temperature durability.

2D Technical Drawings: Detailed drawings were created for each part, with specific dimensions, tolerances, and assembly instructions.

Assembly Instructions: A simple, user-friendly guide for attaching the holders to the helmet and securing the velcro strap across.

The client received all necessary files, including STL and STEP formats for 3D printing, and was given recommendations for potential manufacturers who could produce the holders via injection molding for mass production. We also provided guidance on potential branding placements, should the client wish to add logos or custom colors in future production runs.